Tier-1 Manufacturing Capabilities

Certified Tier-1 IATF/Q1/iSO1400 Facility

VOXX Automotive, through its commitment to operational excellence and Lean implementation, has grown to become a Tier-1 manufacturing partner to many of the world's largest and most respected Automotive OEMs. In the Company's 115,000 sq. ft. facility in Lake Nona, FL, the Company houses its engineering, quality, supply chain and operations teams, and handles all Tier-1 manufacturing for its global customer base. From the time components are received, through assembly, testing and packing, stringent quality standards are implemented at every point, ensuring not just quality but full compliance with all customer requirements. Manufacturing processes include foam production, steel/post notching, steel assembly, vinyl lamination and headrest cover fabrication, as well as all tooling associated with production. A separate product team assembles the security, keyless entry and remote start systems that are included in many of our programs. Lake Nona also serves as the Company's Center of Excellence for future production innovation.

Certified Production and Assembly Process

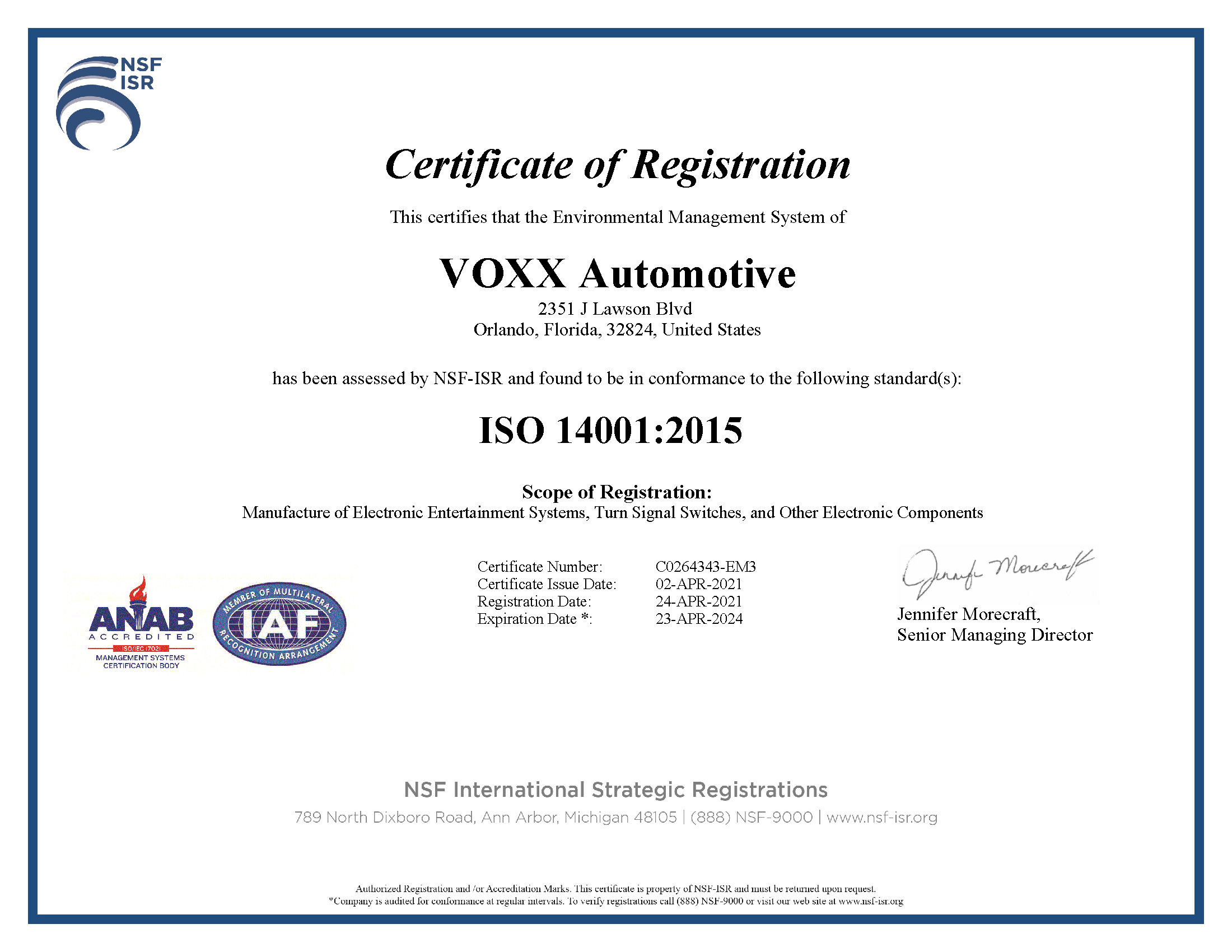

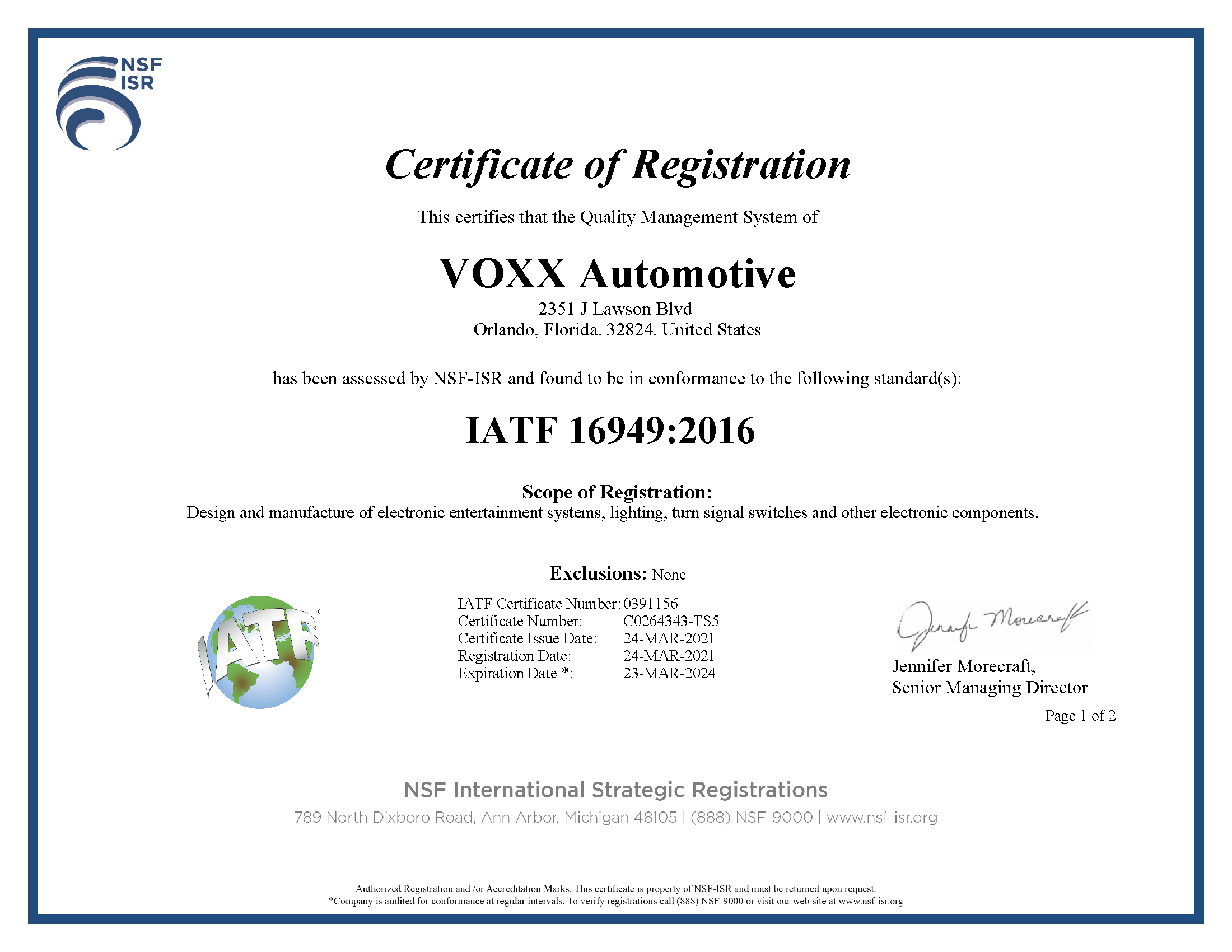

VOXX Automotive is ISO 9000, ISO 14001 and ISO/TS 16949-certified and maintains international status in quality management systems for the majority of products it produces. The Company has also been recognized by Ford Motor Company over the past decade in achieving Q1 status, while receiving various accolades and awards from many of its long-standing OEM partners.

Over the years, the Company has invested in the latest machinery to improve production quality and output, while simultaneously implementing Lean methodologies across its production and assembly lines. The Company employs a Design for Manufacturing and Assembly (DFMA) process, a highly utilized and respected process that reduces time-to-market and total production costs, while simplifying all steps throughout the manufacturing lifecycle. Through the Design for Assembly (DFA) process, VOXX Automotive has been able to reduce assembly time, costs and complexities, which ultimately benefits the customer by developing products quicker and on a lower cost basis.

Global Supply Chain & Logistics

For decades, one of the greatest strengths of VOXX Automotive and its parent company VOXX International Corporation has been its relationships with global supply chain and logistics companies and the processes implemented, to ensure the highest quality products are produced and best-in-class standards are met on behalf of its customers. The design and engineering, supply chain and logistics, and procurement and QC teams collaborate to ensure the right parts are procured and shipped, best-practices in assembly line production are followed, and quality controls are in place at all key touch points along the manufacturing line. This ensures VOXX Automotive continuously meets or exceeds its delivery requirements and quality standards, and sources the very best components utilizing the latest technologies for the most optimal customer output. On-time delivery is one of our strongest and most compelling capabilities.

Engineering

Our success begins with design and development engineers, technicians and program managers working in concert with our customers to design, develop and validate new products that meet the mission-critical needs of their respective consumers. Whether in-car entertainment, remote start systems, vehicle security solutions, or some of our latest innovations not yet in market, we follow the same process with respect to Engineering to ensure that what is designed is manufacturable and meets the price point and technical specifications mandated by our Automotive OEM partners. Engineering is not only done in-house at our factories in Florida and Michigan, it is also performed at customer locations, mod centers, certified installations, and direct-to-dealer-channels.

Our Engineering capabilities include product design and development in Electrical, Mechanical, RF, Software, Production and Validation Engineering, among others. Our teams' partner with customers to work from conceptual design, through product development, certification via testing and validation, into manufacturing, to ensure the highest levels of support during vehicle service and warranty. We support our customers with vehicle systems integration and traditional product development capabilities, integrating diverse features and functions into our solutions that help our customers differentiate themselves in the market and meet the ever-changing demands of consumers.

Among the services offered include:

- Industrial Design

- Electrical and Electronic Circuit Design

- Embedded and Mobile Application Software Development

- Network Communications Development

- Mechanical Engineering Design and Development

- Mechanical and Electrical Systems Integration

- Design for Manufacturing, Assembly & Service